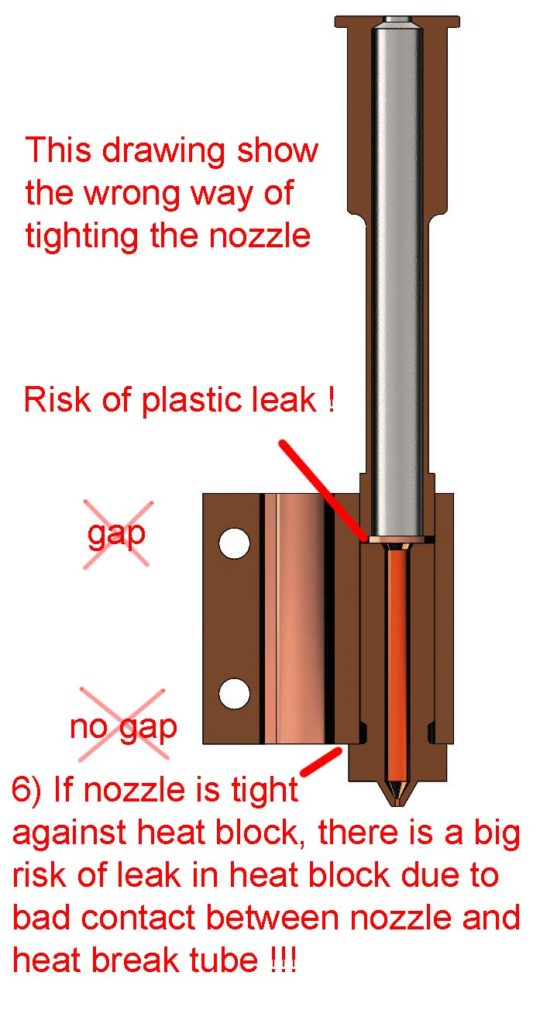

This is a common situation when there is a leakage of plastic in the heat block.

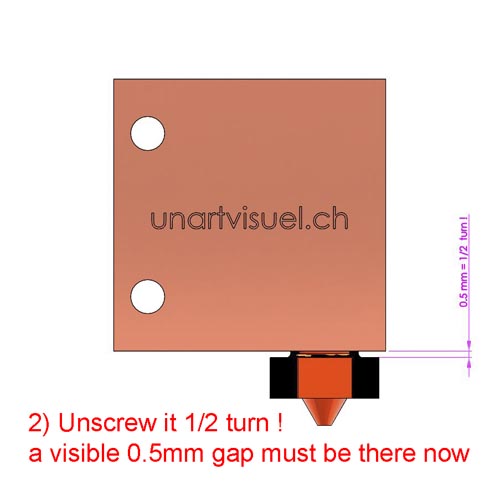

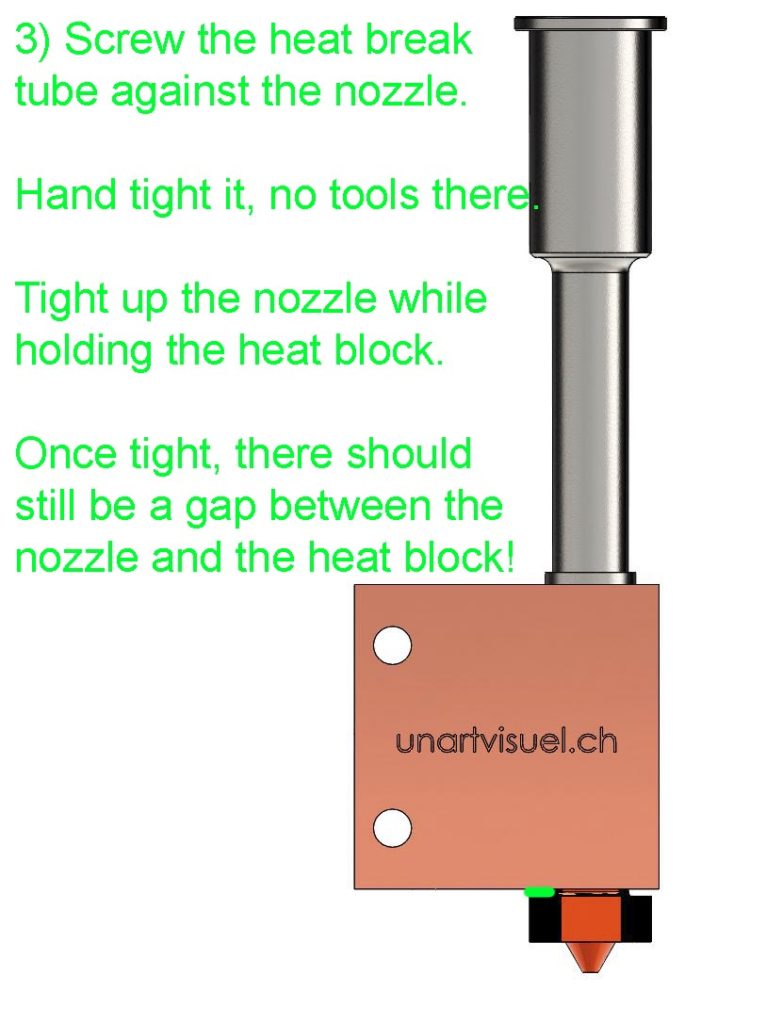

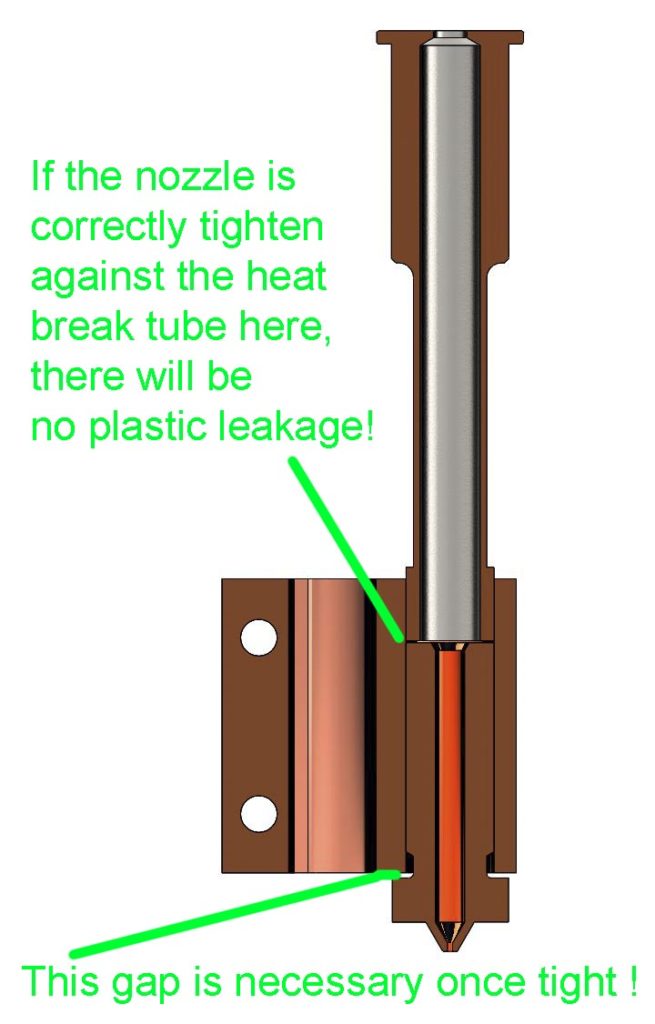

Remember, the nozzle MUST always have a gap between the heat block and the nozzle. The tightness is done between the nozzle and the heat break tube, not between the nozzle and the heat block! Never hold the heat break tube to tighten it. It will be tighten when the nozzle will be in contact with it, so tighten the nozzle as mentioned here under.

Once tight, you can mount the hot end onto the single extruder. Make sure it is perpendicular.

Tight up the screws holding the aluminium plates squeezed between the single extruder lateral plates.

Adjust the position of the heat block to make it parallel to the X axis.

All this shown, it should avoid you having plastic leakage in the heat block.

One more thing, to ensure the tightness of the nozzle, add a keystroke again when the heat block is at 200°C.

Hold both Heat Block and Nozzle, once done, check that this famous gap (it can be a little less than 0.5mm) is still there between the nozzle and the heat block.

Enjoy your prints.